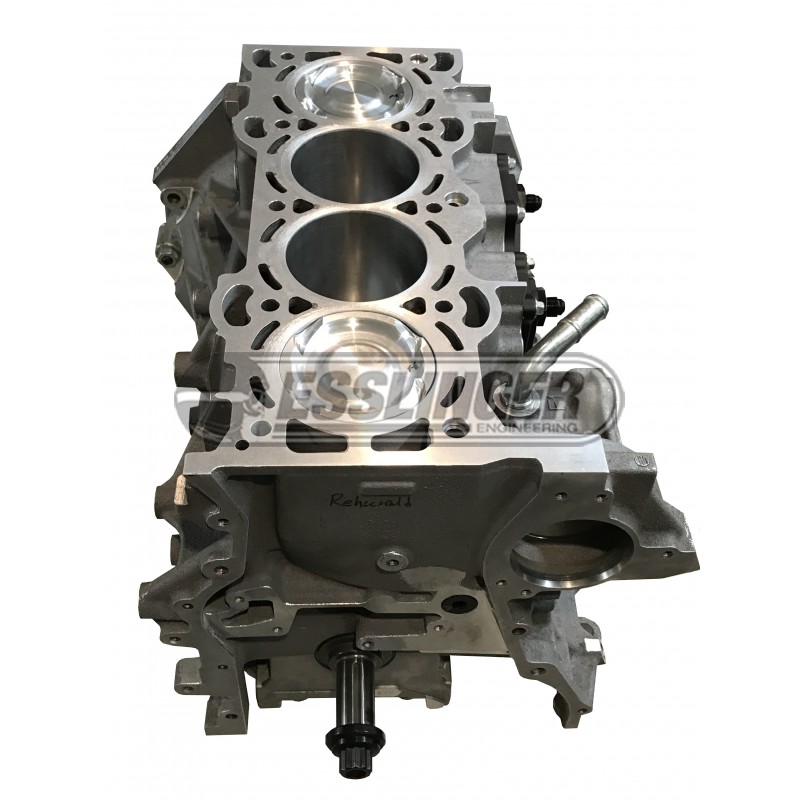

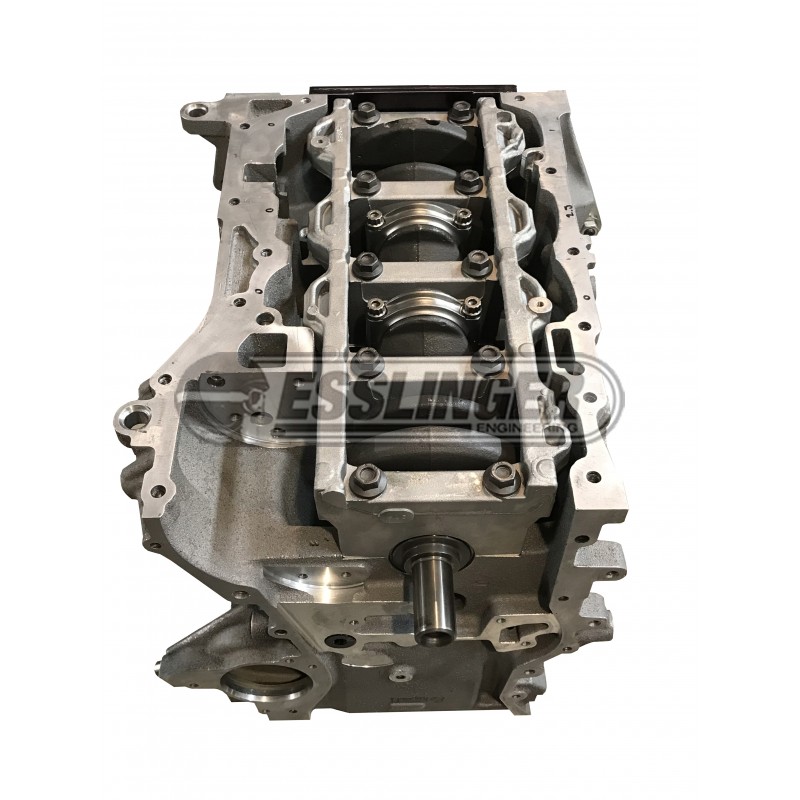

Brand new OEM Ford 2.5L Duratec block

Nominal Bore Size: 89mm (3.504")

Nominal Deck Height: 231mm (9.094")

Machinework Options:

High Performance Machinework & Parts Package A:

Labor: First thing we do is drill & tap all the oil galleys for thread-in o-ring sealed plugs (we don't use or recommend the factory rivet galley plugs). Next, our technician will deck the block so it's square from front to rear & side to side to our exacting tolerances. After the block is decked, the tech will install a torque plate using the style of head fasteners (OEM Torque-to-Yield head bolts, 10mm ARP 8740 head studs, or 10mm Custom Age 625+ head studs) our customer will be using during the build. Once the torque plate has been installed and the fasteners have gone through their initial torque cycles, a tech will then hone the cylinders to 87.55mm (3.447"), or 88mm (3.464") to get the cylinders round and straight, the correct cylinderwall clearance, and the correct surface finish. Then we completely debur the block and prep it for shipping or assembly if we're doing the build in-house. The last thing our tech will do before the block ships is install the hot-water bypass tube into the waterpump housing on the block.

Parts: (10) New OEM main bolts, (1) waterpump bypass tube, (2) -8AN oil galley plugs, (1) -4AN oil galley plug, (1) 1/8"npt oil galley plug),(1) 3/4"npt block plug,

(2) head dowels, and (4) block dowels.

High Performance Machinework & Parts Package B:

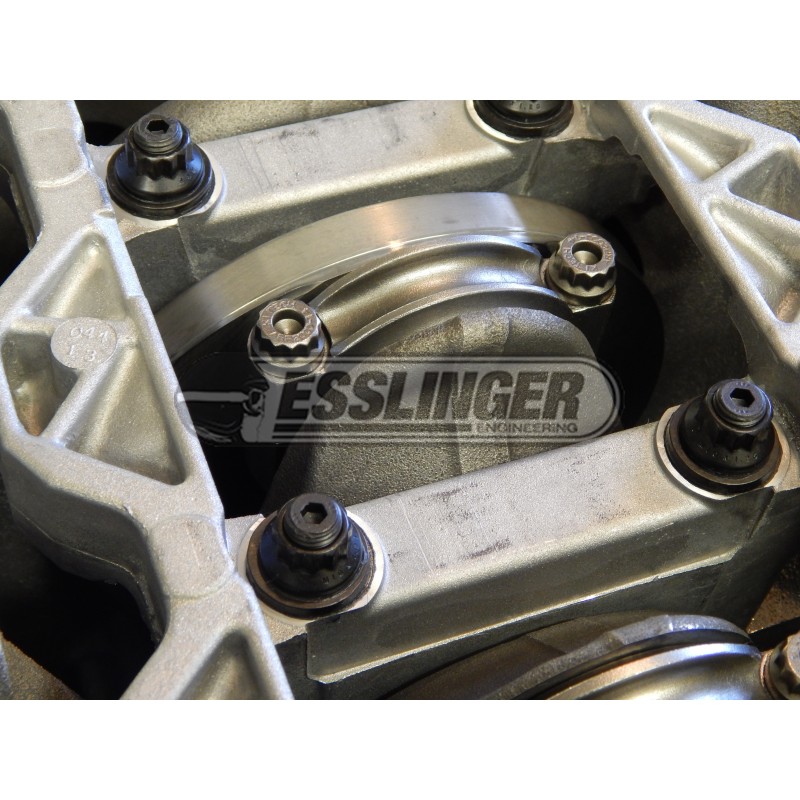

Labor: Includes all machinework in package B, plus our tech will install an ARP main stud kit, after which we then machine .002-.004" off the main ladder (girdle) to get everything true and square. After the re-machined main ladder is torqued up correctly, a technician will hone the main bearing bores to exacting tolerances so that everything is back round and to size with the stronger stud kit. Many other shops skip the align-hone process because it takes specialty tools and extra time, but we've found the main bearing bores out of round by.001-.0015" after installing the stronger main studs! This is especially disturbing when the total clearance is only .0015" on some of these engines. What that means is you could end up with the crankshaft that doesn't have enough vertical oil clearance without the align-hone process done!

Parts: (1) ARP Main Stud Kit plus all the parts from package A except for the OEM TTY main bolts.

High Performance Machinework & Parts Package C:

Labor: Includes all machinework in package B, plus our tech will machine for, and install our 12mm Tool Steel Ultra-Duty Head Stud Kit. Our technician lines up on each individual head stud hole and bores, drills, and then taps the block for our 12mm (stock is 10mm) Ultra-Duty head studs. This process actually improves the resistance to thread pull out as well as increasing the clamp load on the head gasket!

Parts: (1) Esslinger 12mm Tool Steel Ultra-Duty head stud kit plus all the parts from package B.

Why do we do a Torque plate hone on all the blocks we machine?

By torqueing up a torque plate we can simulate the cylinderwall distortion that happens with the head torqued in place. On these blocks, we've seen cylinder roundness change over .001" when torqueing a head in place, that's why this option is so important. We use a Mitutoyo Profilometer to measure the surface texture of each cylinder at multiple points and adjust our Sunnen hone to get the perfect finish for maximum ring seal.

***Check with our staff for a current time frame for any shop labor before purchasing***